In the past, earlier car models had many sources of audio system noise. Advancement in car production has mostly eliminated those sources, and the remaining noises these days typically relate to either grounding or power wire issues.

Engineers design and test amplifiers at a given voltage with a set amount of current. If you want your amplifier to meet its ratings for power, distortion and signal-to-noise, you need to provide those same conditions. The proper power and ground wires and their connections are absolutely critical to amplifier performance. It may cost a little more now, but it will save you big money later.

Choosing the Right Power Wire Gauge Using Your Amplifier Draw

A power wire takes power in DC amperage (or current) to produce power in AC watts. To get that current to the amp, you’ll need a heavy gauge wire. The longer the run, the heavier the wire gauge needs to be. Starving the amp for current will not only reduce its power, but will also shorten its life and could cause total amplifier failure. Use this chart to help you calculate the wire gauge required to move the current from the battery to the amplifier without power loss.

Choosing Ground Wire Gauge and Testing the Ground Connection

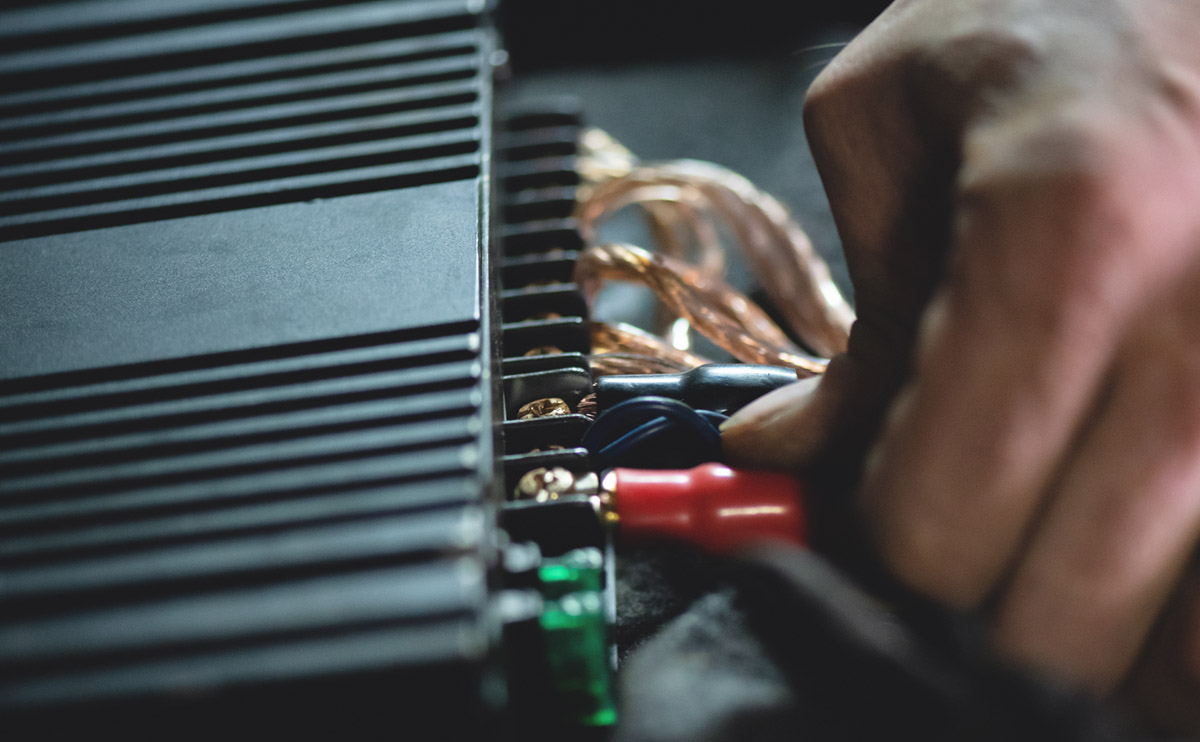

Electricity flows in a circuit from the battery positive to the amplifiers and runs to the battery negative (ground). This flow is determined by the smallest gauge wire in the circuit. So, if you have a 2-gauge wire for power and a 4-gauge wire for ground your whole circuit would only move the current as if it were all 4-gauge wire. You must always use the same gauge wire for Power and for Ground, or you will starve your amp for current. Always sand, scrape, or wire brush the ground location to remove all paint and dirt so you are grounding to bare metal. We recommend grounding to the vehicle frame if possible.

Testing the ground connection:

- Using a multi meter set to read ohms, measure from the battery negative terminal to the bolt at the battery ground connection on the chassis. Ideally it should be 0, but always less than 2 ohms.

- Take the same measurement from the amplifier negative terminal to where the amplifier will be grounded. These two measurements should be the same, and the lower the better. If they are not the same, measure some other ground points to bring the higher resistance measurement down to match the lower one.

The best grounding procedure is to add a heavy gauge wire from the battery negative terminal to the vehicle frame and a heavy gauge wire from the amplifier negative terminal to the frame.

Choosing the Right Type of Wire

With the rising price of copper, many companies are now offering CCA (Copper Clad Aluminum) wire at a lower price. With the advent of CCA wire we now have a new set of problems. Melted wires, melted terminal blocks, and amplifiers that cannot make their rated power, not to mention the extra amp failures.

CCA wire is aluminum wire with a thin coating of copper on the outside. Copper is an excellent conductor of DC current, which is why it has become the industry standard. Aluminum is a poor conductor of DC current. It oxidizes faster than copper, making it corrode much more quickly, leaving open spaces between the wire strands and arcing. This causes CCA wire to get extremely hot as the amp tries to draw the current it needs and can melt the terminal blocks or the insulation from the wire, and increases the likelihood of amp failure.

Aegis Distribution and our manufacturers do not warranty amplifiers unless they are used with 100% copper wire. Look for OFC (Oxygen Free Copper) wire. You have good money invested in your system. Don’t risk it all on cheap wire. All this may sound like a lot of trouble but it doesn’t take that long or cost much, and if you follow these steps you will have less noise, more power, better sound, and longer amplifier life.